A black walnut cutting board combines stunning visual appeal with exceptional durability, making it one of the most sought-after choices for home cooks and professional chefs alike. These premium hardwood boards offer the perfect balance between knife-friendliness and long-lasting performance, all while adding a touch of elegance to any kitchen. Whether you’re considering your first walnut board or upgrading from other materials, understanding what makes black walnut special will help you make an informed investment in a kitchen essential that can last decades with proper care.

In this comprehensive guide, we’ll explore everything you need to know about black walnut cutting boards—from their unique material properties and safety considerations to choosing the right size and maintaining your board for maximum longevity. You’ll discover why end grain construction commands premium prices, how to address common toxicity concerns, and what separates quality craftsmanship from mass-produced alternatives.

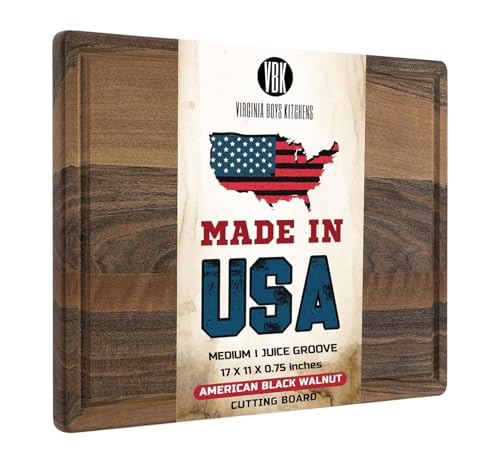

What Makes Black Walnut Cutting Boards Special?

Black walnut cutting boards stand out in the crowded cutting board market for several compelling reasons that go beyond aesthetics. This North American hardwood delivers a rare combination of beauty, functionality, and durability that few other materials can match.

Rich Aesthetic Appeal

The most immediately striking feature of black walnut cutting boards is their gorgeous chocolate brown color with darker streaking throughout the grain. Unlike lighter woods like maple or beech, walnut creates dramatic visual contrast against most kitchen color schemes and makes food preparation feel more like an art form. The rich grain patterns feature swirling, varied tones ranging from deep espresso to lighter caramel hues, ensuring each board is truly one-of-a-kind. This natural beauty means your cutting board doubles as a stunning serving platter for charcuterie, cheeses, and artisan breads, elevating everyday meals into Instagram-worthy presentations.

Optimal Hardness for Kitchen Use

Black walnut registers at 1,010 on the Janka hardness scale, positioning it in what woodworkers call the “Goldilocks zone” for cutting boards. This rating means it’s hard enough to resist deep cuts and scarring from daily use, yet soft enough to be gentle on your expensive kitchen knives. Harder woods like maple (1,450 Janka) can dull knife edges more quickly, while softer woods show excessive wear and require more frequent replacement. Walnut’s moderate hardness allows the wood fibers to close back up after being cut, creating a self-healing surface that maintains its smooth appearance even after years of chopping vegetables, slicing meat, and dicing herbs—much like choosing the right cookware material affects your cooking performance.

Natural Antimicrobial Properties

Research has shown that hardwood cutting boards, including black walnut, possess natural antimicrobial properties that make them safer than plastic alternatives. The wood’s cellular structure actually pulls bacteria below the surface where they cannot multiply and eventually die off, rather than allowing them to thrive in knife scars like plastic boards. While no cutting board eliminates the need for proper cleaning, black walnut’s tight grain structure and natural resistance provide an extra layer of food safety. Combined with regular washing and proper maintenance, these boards create a hygienic food preparation surface that improves rather than degrades with age.

Is Black Walnut Good for Cutting Boards? (Expert Analysis)

If you’re wondering whether black walnut justifies its premium price tag, the answer depends on your priorities and cooking habits. Let’s break down the key performance factors that determine whether black walnut cutting boards deliver genuine value for your kitchen.

Durability and Longevity

Black walnut cutting boards regularly last 15-20 years with proper maintenance, and many well-cared-for boards remain functional for 30+ years or even become family heirlooms. The wood’s stable cellular structure resists warping, cracking, and splitting better than many alternatives, especially when boards are kept properly conditioned with mineral oil. Unlike bamboo boards that can develop splinters or cheap wooden boards that crack after minimal use, quality black walnut boards maintain structural integrity through thousands of cutting sessions. The initial investment of $100-$300 translates to pennies per use over the board’s lifetime, making it more economical than replacing cheaper boards every 2-3 years.

Knife Edge Preservation

Professional chefs often prefer black walnut cutting boards specifically because they preserve expensive knife edges significantly better than harder surfaces. The wood’s moderate density means knife blades sink slightly into the surface rather than striking an unyielding barrier, reducing the microscopic chips and dulling that occur with harder materials. End grain black walnut boards take this benefit even further—the vertical wood fibers actually separate and then close around the blade, essentially “healing” after each cut. Home cooks who invest in quality Japanese or European knives find that walnut boards help maintain factory sharpness much longer between professional sharpening sessions.

Maintenance Requirements

Black walnut cutting boards require more attention than plastic alternatives, which represents the main trade-off for their superior performance. You’ll need to apply food-grade mineral oil monthly (more frequently in the first few months) to prevent the wood from drying out and cracking. These boards must be hand-washed with warm soapy water and never placed in dishwashers, where heat and harsh detergents would destroy the wood. You should also avoid leaving walnut boards soaking in water or storing them where one side stays consistently wet. For busy households or cooks who prefer low-maintenance tools, this care commitment might feel excessive, though most owners report the routine becomes second nature within weeks—similar to maintaining other quality kitchen appliances.

Value for Money

Black walnut cutting boards typically cost $80-$150 for edge grain boards in standard sizes, $150-$250 for end grain boards, and $250-$400+ for large end grain or artisan-crafted pieces. While this represents 3-5 times the cost of basic bamboo or plastic boards, the longevity calculation tells a different story. A $200 black walnut board used for 20 years costs $10 annually, while replacing a $40 plastic board every 3 years costs $13.33 annually—plus plastic boards lack the aesthetic appeal, knife preservation, and antimicrobial benefits. For serious home cooks who prepare meals daily, the premium price becomes an investment rather than an expense, especially considering the board’s dual functionality as both prep surface and serving piece.

| Feature | Black Walnut | Maple | Cherry |

|---|---|---|---|

| Janka Hardness | 1,010 lbf | 1,450 lbf | 995 lbf |

| Knife-Friendliness | Excellent | Good | Excellent |

| Durability | Excellent (15-20+ years) | Excellent (20+ years) | Very Good (12-18 years) |

| Price Range | $80-$400 | $60-$300 | $70-$350 |

| Aesthetic | Dark chocolate brown | Light blonde | Reddish-brown (darkens) |

| Maintenance | Monthly oiling | Monthly oiling | Monthly oiling |

| Best For | Balanced performance, visual impact | Maximum durability, light kitchens | Aesthetic aging, warmth |

Black Walnut Cutting Board Toxic? Addressing Safety Concerns

One of the most common questions people ask before purchasing is whether black walnut cutting boards are toxic, and this concern deserves a thorough, science-based answer.

Understanding the Toxicity Myth

The confusion about black walnut cutting board toxicity stems from the fact that black walnut trees produce a compound called juglone, which is toxic to certain plants and can cause skin irritation in sensitive individuals when they handle fresh sawdust or bark. However, juglone concentrates primarily in the tree’s roots, leaves, and bark—not in the heartwood used for cutting boards. Furthermore, the finishing process and the wood’s curing eliminates virtually all traces of any potentially irritating compounds. Properly finished black walnut cutting boards have been used safely for food preparation for centuries with no documented cases of food contamination or poisoning.

Food-Safe Finishes

The safety of any black walnut cutting board depends entirely on the finish applied during manufacturing. Food-grade mineral oil and beeswax mixtures represent the gold standard for cutting board finishes because they’re completely non-toxic, don’t become rancid, and meet FDA standards for direct food contact. Reputable manufacturers never use toxic finishes like polyurethane, varnish, or Danish oil on cutting boards, as these create barriers that can chip into food and contain harmful chemicals. When purchasing a black walnut cutting board, always verify that it comes with a food-safe finish or is sold unfinished for you to treat with proper mineral oil before first use.

When Black Walnut Is NOT Safe

You should avoid using black walnut cutting boards in a few specific circumstances. Never use raw, untreated black walnut wood for food preparation, as the uncured wood may contain higher levels of natural compounds and hasn’t been properly dried to prevent warping. Individuals with known sensitivities to tree nuts or wood dust should exercise caution, though true allergic reactions to finished walnut boards are extremely rare. If you develop any unexplained skin irritation or respiratory symptoms when using a walnut board, discontinue use and consult a physician. Additionally, boards treated with non-food-safe finishes or those showing mold growth should be discarded rather than repaired.

Black Walnut End Grain Cutting Board: The Premium Choice

Among black walnut cutting boards, end grain construction represents the pinnacle of quality and performance, commanding premium prices for good reason.

What Is End Grain Construction?

End grain cutting boards are constructed by standing wood pieces vertically so the cut surface exposes the ends of the wood fibers, creating a distinctive checkerboard or mosaic pattern. This differs from edge grain boards (wood strips laid on their sides) and face grain boards (wide planks laid flat). Manufacturing end grain boards requires significantly more labor because each piece must be cut, arranged, glued, and then cut again perpendicular to create the vertical fiber orientation. The resulting surface shows the growth rings of the tree, creating stunning visual patterns that make each board a unique work of functional art.

Benefits of End Grain Black Walnut

End grain black walnut cutting boards offer the ultimate self-healing surface where knife blades slip between the vertical wood fibers rather than cutting across them. This means the board shows minimal scarring even after years of heavy use, maintaining its smooth appearance and hygienic surface indefinitely. The construction method also makes these boards exceptionally durable—they can withstand the heavy chopping required for butcher block applications without developing the deep grooves that compromise other cutting boards. The exposed end grain showcases black walnut’s rich color variations and grain patterns to maximum effect, creating a premium aesthetic that justifies displaying the board as kitchen décor when not in use.

Why End Grain Costs More

Black walnut end grain cutting boards typically cost $150-$400 depending on size, compared to $80-$200 for edge grain equivalents. This price premium reflects several factors: the labor-intensive construction requires 3-4 times more manufacturing time, more raw material is needed because of cutting waste during the process, and manufacturers must use higher-grade wood without defects that would compromise the intricate pattern. Additionally, end grain boards require more sophisticated woodworking equipment and expertise to create properly aligned, stable pieces. While the higher cost presents a barrier for budget-conscious buyers, serious cooks view the investment as worthwhile for the superior performance and decades-long lifespan.

Best Uses for End Grain Boards

End grain black walnut boards excel in specific applications that justify their premium price. They’re ideal for heavy-duty chopping tasks like breaking down whole chickens, processing large vegetables, or daily meal prep for families where the board sees intense use. Home butchers and hunters appreciate the durability for processing game and meat. These boards also serve beautifully for entertaining—their striking appearance makes them perfect charcuterie and cheese boards that transition seamlessly from food prep to table service. However, if you primarily need a cutting board for light slicing and occasionally cutting sandwiches, an edge grain board delivers adequate performance at lower cost.

- Still looking for a cutting board that is both beautiful and practical? THETCHRY end grain walnut cutting board is the i…

- Enhance your cooking experience! Our cutting board is not only a tool for cutting vegetables, but also a perfect compani…

- Say goodbye to clutter and make cooking easier! Our cutting Board is designed with a deep juice groove with a capacity o…

Choosing the Right Size: Large Black Walnut Cutting Board Guide

Selecting the proper size represents one of the most important decisions when purchasing a black walnut cutting board, yet it’s often overlooked until after the purchase.

Standard Cutting Board Sizes

Cutting boards generally fall into three size categories that suit different needs. Small boards (10×14 inches or smaller) work for limited prep tasks like slicing sandwiches, cutting fruit, or small kitchens with minimal counter space, though they feel cramped for serious cooking. Medium boards (12×18 inches) represent the most popular size for everyday home cooking, providing enough room for chopping vegetables and preparing typical recipes without overwhelming standard counter spaces. Large boards (15×20 inches and up) offer restaurant-style workspace for ambitious cooks, meal preppers, and anyone who regularly prepares multi-ingredient dishes or large quantities of food.

When to Choose a Large Black Walnut Cutting Board

A large black walnut cutting board makes sense if you regularly cook for families or groups, as the extra space prevents ingredients from spilling off the edges when you’re chopping multiple items simultaneously. Serious home cooks who follow complex recipes requiring multiple prepared ingredients appreciate having room to organize everything on one surface. Large boards also suit anyone who preps meals in advance—you can break down several heads of vegetables or multiple proteins without constant interruptions to transfer ingredients to bowls. The substantial surface area works beautifully as a serving centerpiece for dinner parties, charcuterie spreads, or holiday gatherings. However, you’ll need adequate counter space for use and storage, plus these boards often weigh 15-25 pounds, making them semi-permanent counter fixtures rather than boards you move frequently.

Size Selection Factors

Before selecting a size, measure your available counter space and ensure the board fits with at least 4-6 inches of clearance on all sides for comfortable working room. Consider your storage options—large boards rarely fit in drawers and need vertical storage solutions or permanent counter placement. Think about the board’s weight when wet; a large end grain black walnut board can weigh 20+ pounds after washing, which may be challenging for some users to handle safely. Evaluate your primary use cases realistically: if you mostly prepare simple meals for one or two people, a medium board likely suffices, while competitive home cooks or those who entertain frequently will use every inch of a large board.

Thickness Matters Too

Beyond length and width, cutting board thickness significantly impacts stability and longevity. Standard thickness ranges from 1.5 to 2 inches, providing adequate durability for typical home use while keeping weight manageable. Extra-thick boards measuring 2.5 to 3 inches fall into the butcher block category, offering maximum stability that prevents the board from sliding during aggressive chopping, plus the thick profile can be resurfaced multiple times over decades of use. Thicker boards cost more due to increased material and look more substantial, but they also weigh considerably more—a 2-inch thick 18×24 board might weigh 20 pounds, while a 3-inch version could exceed 30 pounds.

| Size Category | Dimensions | Best For | Typical Weight | Price Range |

|---|---|---|---|---|

| Small | 10×14″ to 12×16″ | Singles, small kitchens, light prep | 5-8 lbs | $80-$150 |

| Medium | 12×18″ to 15×20″ | Everyday cooking, most households | 10-15 lbs | $120-$220 |

| Large | 16×20″ to 20×24″ | Serious cooks, meal prep, entertaining | 15-25 lbs | $180-$350 |

| Extra Large | 20×24″+ | Professional use, permanent fixtures | 25-35+ lbs | $300-$500+ |

- SIZE MATTER! : 1.7″ Thickness for stability, 100% sustainable black walnut wood grown in America for long-lasting. We ma…

- SIMPLE & SOPHISTICATED DESIGN : Presenting our exclusive 3 in 1, butcher block / wood cutting board / serving board tray…

- EASY TO CLEAN : Simply use mild soap and warm water to hand wash the meat cutting board. Do not place in a dishwasher. A…

How to Care for Your Black Walnut Cutting Board

Proper maintenance determines whether your black walnut cutting board lasts five years or fifty years, making care knowledge essential for protecting your investment. For more guidance on maintaining quality kitchen tools, proper care routines ensure maximum longevity.

Initial Seasoning

New black walnut cutting boards require initial seasoning before first use, even if they arrive pre-oiled from the manufacturer. Apply a generous coating of food-grade mineral oil to all surfaces—top, bottom, and edges—using a clean cloth or paper towel, working the oil into the wood until it stops absorbing. Let the board sit horizontally for at least 4-6 hours (overnight is ideal) to allow maximum oil penetration. Wipe away any excess oil that hasn’t absorbed, then apply a second coat and let it rest another 4-6 hours. This initial deep conditioning fills the wood’s cellular structure with protective oil that prevents water absorption, warping, and cracking during regular use.

Regular Maintenance Schedule

During the first three months of ownership, oil your black walnut cutting board weekly to establish a protective moisture barrier. After this break-in period, monthly oiling typically suffices for boards used several times per week. Signs that your board needs treatment include a dry, grayish appearance, raised wood fibers that feel rough, or water that absorbs quickly rather than beading on the surface. High-use boards or those in dry climates may require bi-weekly oiling year-round. Apply mineral oil liberally, let it soak in for several hours, then wipe away excess—the entire process takes about 10 minutes of active time. Every few months, supplement mineral oil with a beeswax and mineral oil conditioner (often called “board butter”) that creates additional water resistance.

Daily Cleaning Best Practices

After each use, wash your black walnut cutting board promptly with warm soapy water and a soft sponge or dishcloth, scrubbing gently to remove food particles and residue. Never put the board in a dishwasher—the extreme heat, harsh detergents, and prolonged water exposure will crack and warp even the highest-quality boards beyond repair. Rinse thoroughly with warm water to remove all soap, as residue can affect food flavor and dry out the wood. Immediately towel-dry both sides of the board, then stand it vertically or prop it at an angle against your backsplash so air circulates around all surfaces. Never lay a wet board flat on the counter or store it while damp, as this promotes mold growth and causes one side to retain moisture, leading to warping.

Deep Cleaning and Stain Removal

For stubborn stains from beets, berries, or turmeric, create a paste using three parts baking soda to one part water, spread it over the stained area, and let it sit for 5-10 minutes before scrubbing with a damp cloth. An alternative method uses half a lemon dipped in coarse salt, which you scrub across the board in circular motions—the salt acts as a gentle abrasive while the lemon’s natural acid helps lift stains and eliminate odors. For deep scratches or grooves that trap bacteria, lightly sand the affected area with 220-grit sandpaper following the wood grain, then immediately apply mineral oil to reseal the wood. If your board develops extensive scarring or deep grooves across the entire surface, professional resurfacing can remove a thin layer of wood to restore a smooth, hygienic surface.

Storage Tips

Store black walnut cutting boards vertically whenever possible, using a plate rack, specialized cutting board rack, or simply leaning them against your backsplash. Vertical storage ensures even air circulation that prevents moisture accumulation and warping. Keep boards away from heat sources like stovetops, ovens, and dishwashers, as heat accelerates moisture loss that leads to cracking. In very dry climates or during winter months when indoor heating reduces humidity, you may need to increase oiling frequency to compensate for accelerated moisture loss. Never store cutting boards in closed cabinets while damp, and avoid stacking multiple wet boards directly on top of each other, as this traps moisture and promotes mold.

- FOOD SAFE MINERAL OIL FOR CUTTING BOARD: Our Food Grade Cutting Board White Mineral Oil is a smooth, lightweight oil; id…

- CUTTING BOARD OIL TO REFRESH CUTTING BOARD: This USP & Food Grade Mineral Oil for cutting board protects wooden cookware…

- BUTCHER BLOCK OIL: Mineral oil can be used a butcher block conditioner and as a wood oil for cutting board; our food-gra…

Black Walnut vs. Other Wood Cutting Boards

Understanding how black walnut compares to alternative hardwoods helps you make the right choice for your specific needs and preferences. For a comprehensive comparison of different wood types for cutting boards, explore detailed material analysis.

Black Walnut vs. Maple

Maple cutting boards rate 1,450 on the Janka hardness scale compared to walnut’s 1,010, making maple significantly harder and more durable but also tougher on knife edges. Maple’s light blonde color creates dramatic contrast for food photography and brightens kitchens, while walnut’s dark chocolate tones add warmth and luxury but show flour and light-colored ingredients more visibly. Maple boards typically cost 15-25% less than comparable walnut boards due to wider availability and easier sourcing. For maximum board longevity and resistance to deep cuts, maple wins, but for knife preservation and aesthetic richness, black walnut takes the advantage. Many serious cooks own both types and use maple for heavy-duty tasks like pounding cutlets and walnut for precision knife work.

Black Walnut vs. Cherry

Cherry and black walnut offer similar hardness levels (cherry registers around 995 on the Janka scale), making them nearly equivalent for knife-friendliness and day-to-day durability. The key difference lies in their aging characteristics—cherry starts reddish-brown and darkens significantly to deep reddish-amber over time with light exposure, while black walnut actually lightens slightly from dark chocolate to a lighter brown. Cherry’s color evolution creates a living patina that some owners love and others find inconsistent, whereas walnut maintains more stable coloring throughout its life. Price-wise, the boards run comparable, with cherry sometimes commanding premiums when figured or heavily grained pieces are used. Both woods offer excellent performance, making the choice primarily aesthetic.

Black Walnut vs. Teak

Teak cutting boards contain natural oils that make them highly water-resistant and lower-maintenance than black walnut, requiring less frequent conditioning and resisting warping better in humid climates. However, teak’s natural oils can occasionally impart subtle flavor to delicate foods, and its harder density (1,155 Janka) makes it slightly tougher on knife edges than walnut. Teak costs 30-50% more than black walnut in most markets due to importation costs and sustainability concerns around tropical hardwood sourcing. Teak’s golden-brown color with darker streaking offers different aesthetics than walnut’s chocolate tones. For cooks prioritizing low maintenance and water resistance, teak excels, while those seeking the best balance of knife-friendliness, aesthetics, and value favor black walnut.

| Comparison Factor | Black Walnut | Maple | Cherry | Teak |

|---|---|---|---|---|

| Janka Hardness | 1,010 lbf | 1,450 lbf | 995 lbf | 1,155 lbf |

| Knife-Friendliness | Excellent | Good | Excellent | Very Good |

| Water Resistance | Good | Good | Good | Excellent |

| Maintenance Need | Monthly oil | Monthly oil | Monthly oil | Bi-monthly oil |

| Color | Dark chocolate brown | Light blonde | Reddish (darkens) | Golden brown |

| Typical Price (18×12″) | $120-$180 | $90-$140 | $110-$170 | $150-$230 |

| Longevity | 15-20+ years | 20-25+ years | 12-18 years | 20-25+ years |

| Best For | Balanced performance | Maximum durability | Warm aesthetics | Low maintenance |

What to Look for When Buying Black Walnut Cutting Boards

Knowing quality indicators helps you avoid disappointing purchases and ensures you get genuine value for your investment.

Quality Indicators

The most important distinction is solid wood versus veneer—quality black walnut cutting boards use solid hardwood throughout, while cheaper versions apply a thin walnut veneer over cheaper wood cores that can separate and fail. Examine grain orientation and pattern consistency; well-made boards show consistent grain alignment without significant gaps, mismatched pieces, or obvious defects. Run your hand across the surface to verify it feels completely smooth without rough patches, raised fibers, or sticky finish residue. Inspect all glued joints carefully—they should be nearly invisible with no gaps, and the board should feel like one solid piece rather than separate strips that might separate. High-quality boards feel substantial and dense without any hollow areas.

Thickness and Weight

Quality cutting boards measure at least 1.5 inches thick for stability and long-term durability—thinner boards flex during use and warp more easily as they age. A properly sized board should feel surprisingly heavy; a 12×18 inch walnut board under 8 pounds likely uses lower-density wood or is too thin. The weight-to-size ratio indicates the board will sit firmly on your counter without sliding during vigorous chopping. End grain boards typically weigh 20-30% more than edge grain boards of equivalent dimensions due to their denser construction.

Edge Details

Well-crafted boards feature gently rounded edges rather than sharp 90-degree corners, making them more comfortable to handle and less likely to chip or splinter. Juice grooves carved around the perimeter are useful for catching liquids when carving roasted meats but create cleaning challenges and reduce usable cutting surface—decide whether this trade-off suits your needs. Handles or hand-holds add convenience for moving large boards but can interfere with using the full surface and may weaken structural integrity if poorly designed. Check whether the board is reversible (both sides smooth and usable) or single-sided—reversible boards offer better value though end grain boards are typically single-sided due to their construction.

Craftsmanship Signs

Hand-made or small-batch boards typically show subtle variations that indicate individual craftsmanship rather than mass production, though this doesn’t automatically guarantee superior quality. Research the maker’s reputation through reviews and customer feedback—established craftspeople stand behind their work and often offer care guidance. Verify wood sourcing when possible; domestically sourced American black walnut from sustainable forests provides better quality control than imported wood of uncertain origin. Look for warranties, satisfaction guarantees, or return policies that demonstrate the maker’s confidence in their product. Artisan makers often sign or mark their boards, which adds value and indicates pride in craftsmanship.

Price Expectations

Budget-friendly black walnut boards ($80-$150) typically feature edge grain construction in smaller sizes (12×16 inches or less), may be thinner (1.25-1.5 inches), and come from larger manufacturers rather than artisan makers. Mid-range options ($150-$250) usually offer end grain construction in medium sizes (14×18 to 16×20 inches), proper thickness (1.75-2 inches), and may include premium features like hand-rubbed finishes or figured wood. Premium boards ($250-$400+) feature large end grain construction, exceptional thickness (2.5+ inches), artisan craftsmanship with attention to detail, exotic grain patterns, and often custom sizing or personalization. Understanding these price tiers helps set realistic expectations and identify genuine value versus overpriced marketing.

Top 5 Black Walnut Cutting Board Picks (2025)

Based on construction quality, value, and user satisfaction, these categories represent the best options for different needs and budgets.

| Category | Size Range | Construction | Price Range | Best For |

|---|---|---|---|---|

| Best Overall | 14×18″ to 16×20″ | End grain | $180-$280 | Serious home cooks wanting premium performance |

| Best Large Board | 18×22″ to 20×24″ | End grain | $280-$400 | Meal preppers, families, entertainers |

| Best End Grain | 15×20″ | End grain | $220-$320 | Knife enthusiasts, heavy daily use |

| Best Budget | 12×18″ | Edge grain | $80-$140 | First-time buyers, occasional cooks |

| Best Artisan | Custom sizes | End grain | $300-$500+ | Gift-giving, heirloom pieces, design lovers |

1. Best Overall Black Walnut Cutting Board

Look for end grain construction in the 14×18 to 16×20 inch range with 1.75-2 inch thickness from established makers with strong reputations. These boards balance generous working space with manageable weight (12-18 pounds), making them practical for daily use while offering premium end grain benefits. Quality examples feature tight, consistent grain patterns with food-safe mineral oil and beeswax finishes, reversible designs for extended life, and rubber feet to prevent slipping.

Best for: Serious home cooks who prepare meals 4-5 times weekly and want a board that performs beautifully while serving as kitchen décor, similar to investing in quality kitchen appliances.

Pros: Perfect size for most recipes, excellent knife preservation, striking appearance, 20+ year lifespan, doubles as serving board.

Cons: Requires monthly maintenance, significant investment ($180-$280), too heavy for some users when wet, needs vertical storage.

- [SAFE CUTTING BOARD]: This wooden cutting board for the kitchen is made from the walnut wood, finished safely. Solid woo…

- [DEEP JUICE GROOVE WITH BUILT-IN HANDLES]: Surrounded with deep juice groove which close to the edge. This large wooden …

- [REVERSIBLE, MULTIPURPOSE]: This large, smooth walnut wood cutting board boasts a front side with a juice groove design,…

2. Best Large Black Walnut Cutting Board

Large format boards measuring 18×22 inches up to 20×24 inches provide restaurant-style workspace for ambitious home cooking. End grain construction at this size creates substantial pieces weighing 20-30 pounds that function as semi-permanent counter installations. Premium large boards often feature extra thickness (2.5-3 inches) for maximum stability and include juice grooves for meat carving.

Best for: Meal preppers who batch-cook for families, home butchers processing whole animals, entertainers who need dramatic serving pieces for large gatherings.

Pros: Maximum workspace, rarely outgrow the board, impressive visual statement, withstands heavy-duty butchering, excellent resurfacing potential due to thickness.

Cons: Very expensive ($280-$400+), requires substantial counter and storage space, heavy enough to be difficult for some users to move, increased oiling requirements for larger surface area.

- WALNUT END GRAIN – Black walnut wood is one of the best hardwoods, when it comes to long-lasting, high-quality cutting b…

- FUNCTIONAL & VERSATILE – This reversible butcher block measure 17x13x1.5 inch, 8.37 lb, large enough to cut everything f…

- COMES READY TO USE – We understand it’s often a hassle to prepare a cutting board for use. Our wood cutting boards are w…

3. Best Black Walnut End Grain Cutting Board

The sweet spot for end grain performance sits around 15×20 inches with 2-inch thickness, offering excellent surface area without becoming unwieldy. These boards showcase end grain’s self-healing properties and distinctive checkerboard patterns while remaining practical for daily use. Quality examples use select walnut with varied grain for maximum visual interest.

Best for: Knife enthusiasts with quality Japanese or European knives, serious cooks who chop daily, anyone wanting the ultimate cutting surface without extreme size.

Pros: Superior self-healing surface, optimal knife preservation, beautiful end grain patterns, practical dimensions, excellent durability.

Cons: Premium pricing ($220-$320), significant weight (15-20 lbs), requires consistent maintenance, single-sided use due to construction.

- Handmade in the USA from 100% sustainable walnut wood so you can trust the quality, craftsmanship, and locally sourced m…

- Say No to Toxic Imports: Our wooden cutting boards are pure, natural, and safe, made from high-quality American wood and…

- Avoid Microplastics: Wooden cutting boards don’t shed harmful microplastics like plastic boards do, so you can prepare y…

4. Best Budget-Friendly Black Walnut Option

Edge grain boards in the 12×18 inch range offer an accessible entry point to black walnut cutting boards. While lacking end grain’s premium properties, quality edge grain boards still provide walnut’s rich aesthetics, good knife-friendliness, and 10-15 year longevity. Look for 1.5-inch minimum thickness from reputable manufacturers who don’t cut corners on materials or construction.

Best for: First-time walnut board buyers, occasional cooks who don’t need commercial-grade durability, those wanting walnut aesthetics without premium pricing, secondary boards for specific tasks.

Pros: Accessible price point ($80-$140), lighter weight (6-10 lbs) easier to handle, adequate performance for typical home cooking, still offers walnut’s beauty and antimicrobial properties.

Cons: Shows knife marks more than end grain, shorter lifespan than premium boards, may lack craftsmanship details, less impressive visually than end grain construction.

- SOLID WALNUT WOOD: Smooth, knife-friendly surface for daily prep and serving. Deep chocolate to espresso grain adds warm…

- EASY TO CARRY: Designed with convenience in mind, featuring invisible inner handles on both sides for easy transport. Th…

- EASY TO CLEAN: Our cutting board helps keep your kitchen tidy with minimal effort. Crafted with food-safe wax oil finish…

5. Best Artisan/Handcrafted Black Walnut Board

Custom or small-batch boards from skilled woodworkers represent the pinnacle of cutting board craftsmanship. These pieces often feature book-matched grain patterns, custom dimensions to fit specific spaces, hand-rubbed multi-coat finishes, and personalization options like engraving. Artisan makers select premium figured walnut that mass producers can’t economically use, creating truly unique functional art pieces.

Best for: Gift-giving for weddings or milestone occasions, collectors who appreciate fine craftsmanship, cooks wanting heirloom-quality pieces, those with specific size requirements.

Pros: Exceptional attention to detail, unique grain patterns, custom sizing available, conversation-piece aesthetics, direct relationship with maker, often includes lifetime support.

Cons: Highest prices ($300-$500+), may require lead time for custom orders, sometimes too beautiful to use regularly, premium doesn’t always translate to better performance than mid-range options.

- [SAFE CUTTING BOARD] This wooden cutting board for the kitchen is made from the walnut wood, finished safely. Solid wood…

- [DEEP JUICE GROOVE WITH BUILT-IN HANDLES] Surrounded with deep juice groove which close to the edge. This large wooden c…

- [REVERSIBLE, MULTIPURPOSE] This large, smooth walnut wood cutting board boasts a front side with a juice groove design, …

Common Problems and Solutions

Even quality black walnut cutting boards can develop issues without proper care, but most problems have straightforward solutions.

Warping Issues

Warping occurs when one side of the board absorbs more moisture than the other, causing the wood to expand unevenly and bow. This typically happens when boards are laid flat while wet, stored near heat sources, or insufficiently oiled. Catch warping early by wetting both sides of the board evenly, placing weight on top (like cast iron pans), and letting it dry slowly over several days in a humidity-controlled environment. For prevention, always store boards vertically, apply oil to all surfaces equally including edges and bottom, and never leave boards lying in puddles or next to hot appliances. Severely warped boards (over 1-inch deviation) usually cannot be fully corrected and may need professional planing.

Surface Staining

Beets, berries, turmeric, and curry commonly stain black walnut cutting boards, though the dark wood hides discoloration better than light maple. Immediate cleaning prevents most stains from setting—wipe up colorful ingredients as you work rather than letting them sit. For set-in stains, make a paste with baking soda and water, scrub gently with a damp cloth, rinse thoroughly, and oil immediately after the wood dries. Alternatively, cut a lemon in half, dip it in coarse salt, and scrub the stained area in circular motions for 2-3 minutes. Accept that some staining is inevitable with regular use and adds character rather than diminishing the board’s function or safety.

Odor Absorption

Strong ingredients like garlic, onions, and fish can leave lingering odors in cutting boards that transfer to subsequently prepared foods. After cutting aromatic ingredients, wash the board immediately with hot soapy water, then scrub with the lemon-salt method described above—lemon’s citric acid neutralizes odors naturally. For stubborn smells, make a solution of one part white vinegar to four parts water, wipe it across the board, let it sit for 5 minutes, then rinse and dry thoroughly. Prevention works better than treatment: dedicate specific areas of large boards or use separate boards entirely for aromatic vegetables and seafood.

Dried Out or Cracking Wood

Neglected boards develop a grayish, dried-out appearance, rough surface texture, and eventually small cracks that can expand into serious structural problems. Rescue dried boards with intensive conditioning: sand lightly with 220-grit sandpaper to smooth raised fibers, then apply warm (not hot) mineral oil and let it soak in overnight. Repeat this process 3-4 times over two weeks until the wood stops readily absorbing oil. For small cracks (under 1/8 inch), fill the crack with a wood glue and sawdust mixture, clamp overnight, sand smooth, and seal with multiple oil coats. Large cracks or splits that go through the board’s thickness indicate structural failure—these boards should be retired from food prep use and repurposed as trivets or decorative pieces.

Conclusion

Black walnut cutting boards represent one of the finest investments serious home cooks can make, combining exceptional functionality with timeless aesthetic appeal that improves kitchens instantly. The wood’s optimal hardness preserves expensive knife edges while resisting the deep scarring that compromises other cutting boards, and its natural antimicrobial properties contribute to safer food preparation. While these premium boards require consistent maintenance and careful handling compared to synthetic alternatives, the combination of 15-20+ year longevity, dual functionality as prep surface and serving piece, and heirloom quality justifies the investment for anyone who values their quality kitchen equipment.

Whether you choose an edge grain board for budget-conscious performance or invest in end grain construction for ultimate durability, proper care determines your board’s lifespan. Monthly oiling, gentle hand-washing, and vertical storage take just minutes but ensure your black walnut cutting board serves you faithfully for decades. The safety concerns around walnut toxicity are myths when boards feature proper food-safe finishes, so you can confidently prepare everything from delicate herbs to raw proteins on these beautiful hardwood surfaces.

Consider your cooking habits, available space, and budget to select the right size and construction type, then commit to the simple maintenance routine that protects your investment. A quality black walnut cutting board isn’t just a kitchen tool—it’s a daily reminder that cooking deserves beautiful, functional equipment that enhances both the process and the results. Just as you carefully select your best air fryer or perfect waffle maker, choosing the right cutting board elevates your entire culinary experience.

For those who take their food preparation seriously—whether you’re making hash browns in your air fryer or preparing elaborate multi-course meals—a premium black walnut cutting board provides the foundation for knife skills, food safety, and cooking enjoyment for years to come.

You’ve just armed yourself with everything you need to choose, use, and care for a premium black walnut cutting board. But there’s even more to discover about why walnut wood has captured the hearts of professional chefs and home cooking enthusiasts worldwide.

Read: Walnut Cutting Board – Best Wood Choice for Your Kitchen

Frequently Asked Questions

How often should I oil my black walnut cutting board?

Oil your black walnut cutting board weekly for the first three months to establish proper conditioning, then monthly for ongoing maintenance. Boards used daily or in dry climates may need bi-weekly oiling, while occasional-use boards might stretch to every 6-8 weeks. Your board needs oil when the surface looks dry or grayish rather than rich brown, feels rough instead of smooth, or when water absorbs quickly rather than beading on the surface. Always use food-grade mineral oil or specialized cutting board oil—never vegetable, olive, or other cooking oils that turn rancid.

Can black walnut cutting boards go in the dishwasher?

Never put black walnut cutting boards in the dishwasher under any circumstances. Dishwasher heat, harsh detergents, and prolonged water exposure will cause even the highest-quality boards to crack, warp, split, and potentially delaminate within just a few wash cycles. The intense heat strips protective oils from the wood faster than they can be replaced, while detergent residues dry out the cellular structure. Always hand-wash walnut boards with warm soapy water, rinse thoroughly, towel dry immediately, and store vertically. This hand-washing requirement represents the main maintenance trade-off for wood boards’ superior performance compared to dishwasher-safe plastic alternatives.

Are black walnut cutting boards safe for food preparation?

Yes, properly finished black walnut cutting boards are completely safe for food preparation and have been used for this purpose for centuries. The confusion about toxicity stems from juglone, a compound in black walnut roots and leaves that’s toxic to certain plants, but this compound is not present in meaningful amounts in the heartwood used for cutting boards. Quality boards use food-grade mineral oil and beeswax finishes that meet FDA standards for direct food contact. Properly maintained walnut boards actually possess natural antimicrobial properties that make them safer than plastic alternatives. Avoid raw untreated wood and boards with non-food-safe finishes like polyurethane.

What’s the difference between end grain and edge grain black walnut boards?

End grain boards are constructed with wood pieces standing vertically so the board surface shows the ends of wood fibers, creating a checkerboard pattern and self-healing cutting surface where knife blades slip between fibers rather than cutting through them. Edge grain boards lay wood strips horizontally on their sides, creating a striped appearance and a more traditional cutting surface. End grain offers superior knife preservation, shows less scarring over time, and typically lasts longer, but costs 40-60% more due to labor-intensive construction. Edge grain provides good performance at lower cost and lighter weight but will show knife marks more prominently over years of use.

How long do black walnut cutting boards last?

High-quality black walnut cutting boards regularly last 15-20 years with proper maintenance, and many well-cared-for boards remain functional for 30+ years or even become family heirlooms passed down generations. End grain construction typically outlasts edge grain by 5-10 years due to its self-healing properties and superior durability. Lifespan depends primarily on maintenance consistency—boards that receive monthly oiling, proper cleaning, and vertical storage reach their full potential, while neglected boards may fail within 5-7 years through cracking, warping, or structural problems. When boards develop extensive scarring, they can be professionally resurfaced to restore a smooth, sanitary surface and add another decade of use.

Why are black walnut cutting boards more expensive than other woods?

Black walnut costs more than alternatives like maple or bamboo for several reasons. The wood itself commands premium prices due to slower growth rates, limited geographic range (primarily eastern North America), and high demand for furniture and woodworking. Black walnut trees must mature 30-40 years before harvest, compared to faster-growing alternatives. The dark chocolate coloring and striking grain patterns that make walnut desirable also mean woodworkers must select higher-grade boards without defects that would show prominently. Additionally, walnut’s premium positioning allows craftspeople to spend more time on details and finishing. While a walnut board might cost $120-$180 compared to $80-$120 for equivalent maple, many users find the aesthetic appeal and knife-friendliness justify the 30-50% premium.

Can I use olive oil on my black walnut cutting board?

Never use olive oil, vegetable oil, coconut oil, or any cooking oil on cutting boards. These oils turn rancid within weeks, creating sticky residue that smells bad, attracts dust and debris, and potentially contaminates food with off-flavors. Always use food-grade mineral oil (available at pharmacies or kitchen supply stores) or specialized cutting board oil, which never goes rancid because it’s not an organic oil. Mineral oil is completely food-safe, FDA-approved for direct food contact, colorless, odorless, and remains stable indefinitely. Many woodworkers also use board conditioning products that combine mineral oil with beeswax or carnauba wax for enhanced water resistance.

How do I remove deep scratches from a black walnut cutting board?

For deep scratches or grooves, lightly sand the affected area using 220-grit sandpaper, always following the direction of the wood grain rather than sanding across it. Sand gently with even pressure until the scratch disappears and the surface feels smooth—this typically removes only 1/32 to 1/16 inch of material. Wipe away all sanding dust with a damp cloth, let the board dry completely, then immediately apply multiple coats of mineral oil over several hours to reseal the freshly exposed wood. For scratches covering large areas or the entire board surface, professional resurfacing with a planer or belt sander removes a uniform layer across the whole board, restoring factory-smooth conditions. Boards can typically be resurfaced 3-5 times over their lifetime depending on thickness.